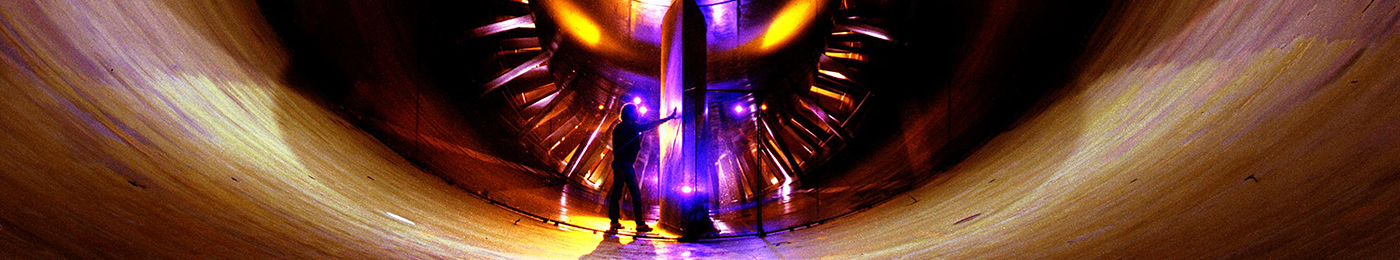

High-Performance Data Acquisition for Wind Tunnel Testing

Large Scale and Small Scale Testing | Dynamic and Static Testing | High Channel Count Data Acquisition Systems | Signal Conditioning Solutions

Precision You Can Trust for Every Wind Tunnel Test

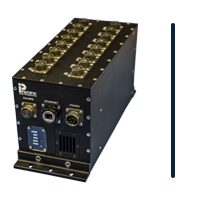

At Pacific Instruments, we understand the complexity and precision required in Wind Tunnel Testing—whether you're conducting large scale aerodynamic simulations or small scale component evaluations, dynamic load assessments or static structural tests. Our high channel count data acquisition systems and advanced signal conditioning solutions are engineered to deliver reliable, high-fidelity data that helps aerospace engineers, researchers, and manufacturers make informed decisions faster.

We help eliminate common pain points such as:

- Inconsistent signal quality across multiple channels

- Limited scalability for high-density sensor arrays

- Integration challenges with legacy systems

- Data loss during high-speed dynamic testing

Core Features That Power Your Testing Success

- High Channel Count Systems: Scalable architecture supporting thousands of channels for comprehensive data capture in complex wind tunnel setups.

- Advanced Signal Conditioning: Precision filtering, amplification, and isolation for strain gauges, thermocouples, pressure transducers, and more.

- Real-Time Data Acquisition & Analysis: High-speed sampling with synchronized data streams for dynamic and static testing environments.

- Modular & Rugged Design: Built to withstand harsh test conditions and easily configurable for different tunnel sizes and test types.

- Seamless Integration: Compatible with industry-standard protocols and legacy systems to streamline deployment.

- Remote Monitoring & Control: Web-based interfaces and remote diagnostics for efficient test management.

Proven Applications in Wind Tunnel Testing

Pacific Instruments' solutions are trusted across leading aerospace and defense organizations:

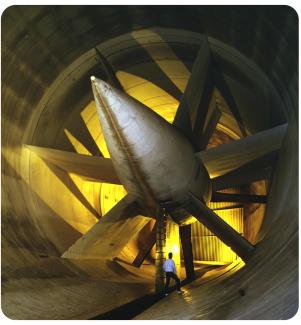

- Large Scale Aerodynamic Testing: Used in full-scale aircraft wind tunnels to measure lift, drag, and pressure distribution with thousands of sensors.

- Small Scale Component Validation: Supports blade, winglet, and fuselage testing with high-resolution data for design optimization.

- Dynamic Load Testing: Captures transient forces and vibrations during simulated flight conditions.

- Static Structural Analysis: Monitors stress and strain under controlled loads to validate material performance.

Case Study: A major aerospace manufacturer deployed our system in a supersonic wind tunnel to monitor over 2,000 channels during dynamic pressure tests. The result: a 30% reduction in test cycle time and a significant improvement in data accuracy.

Ready to Elevate Your Wind Tunnel Testing?

Let’s talk about how Pacific Instruments can help you achieve greater precision, scalability, and efficiency in your aerodynamic testing programs