Series 6700 High Speed Data Acquisition & Control Systems

Introducing the Pacific Instruments Series 6700 High Performance Signal Conditioning and Data Acquisition System, the premier Data Acquisition solution on the market. Based on the widely adopted Pacific Instruments Series 6000 system, the Series 6700 elevates performance and accuracy to levels not previously available.

Designed for Critical Applications

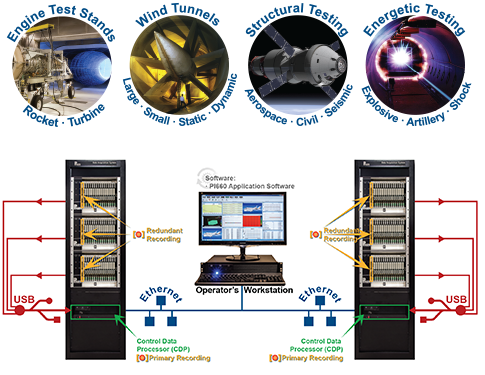

Suited for a wide spectrum of testing needs such as full scale rocket engine, jet turbine engine, structural, wind tunnel and numerous other applications, the Pacific Instruments Series 6700 is designed to meet the most demanding test requirements.

- High Speed Data Acquisition for Large Channel Counts

- Supports Aggregate Rates up to 32Ms/s

- 24-Bit Integrated A/D

- Up to 2Ms/s per Channel

- Turn-key & API Software

Series 6700 Configuration

New Series 6700 Enclosure, Model 6700U, supports systems with massive channel-counts and millions of samples per second. Select Input/Output (I/O) Modules to configure and customize sample rates, measurement types and system controls. Pacific Instruments PI660 Software offers ultimate flexibility with test management, data acquisition, data display, export and analysis.

16-Slot USB High-Speed DAQ Enclosure

Model 6700U

High performance data acquisition enclosure to support systems with massive channel-counts and millions of samples per second.

- Enclosure for 16 I/O modules

- USB 3.0 Interface provides up to 32MS/s aggregate data rate

- Optional on-board data storage

8-Channels

Voltage / IEPE, 200kS/s

Model 6729

The 6729 input module has eight channels, each providing excitation for IEPE transducers with an analog to digital converter.

- 8-Channels AC or DC Coupled Inputs

- Up to 200kS/s per Channel with 16-bit Resolution

- Buffered ±10 Volt Analog Output

8-Channels

Strain / Bridge, 250kS/s

Model 6739

The 6739 input module has eight channels of high performance signal-conditioning amplifier-digitizers for strain gages and bridge transducers.

- 8-Channels for Strain/Bridge Transducers

- Up to 250kS/s per channel with 24-bit resolution

- Suited for demanding, dynamic measurement applications

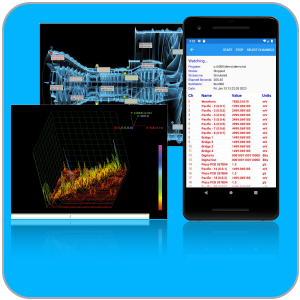

PI660 Software

Data Display & Analysis

Turn-key or API

One comprehensive, low cost software package, no add-ons or hidden fees.

- Turn-key Acquisition

- Real-Time Displays

- 3rd Party Support

|

Download the Series 6700 Product GuideHigh Speed, Superior Performance.

EVERYTHING ELSE IS JUST NOISE |

High Accuracy Data Acquisition with Full-Scale Facility Control

Built with the flexibility to meet changing requirements and seamlessly integrate with existing facility equipment, the Pacific Instruments Series 6700 High Speed Data Acquisition & Control System is the ultimate solution to facility-wide test and measurement applications. Large research and development facilities, such as wind tunnels, rocket engine test stands and structural shake tables benefit from a centralized system that is easy to customize and operate.

Key Features

- Real Time System Control Capabilities

- Unlimited Channels Per System

- 24-bit ΣΔ with the Highest Effective Number of Bits on the Market

- Independent Settings per Channel: Sample Rate, Input Type, Excitation, Filter, Gain etc.

Centralized Recording & Data Backup Redundancy for Mission Success

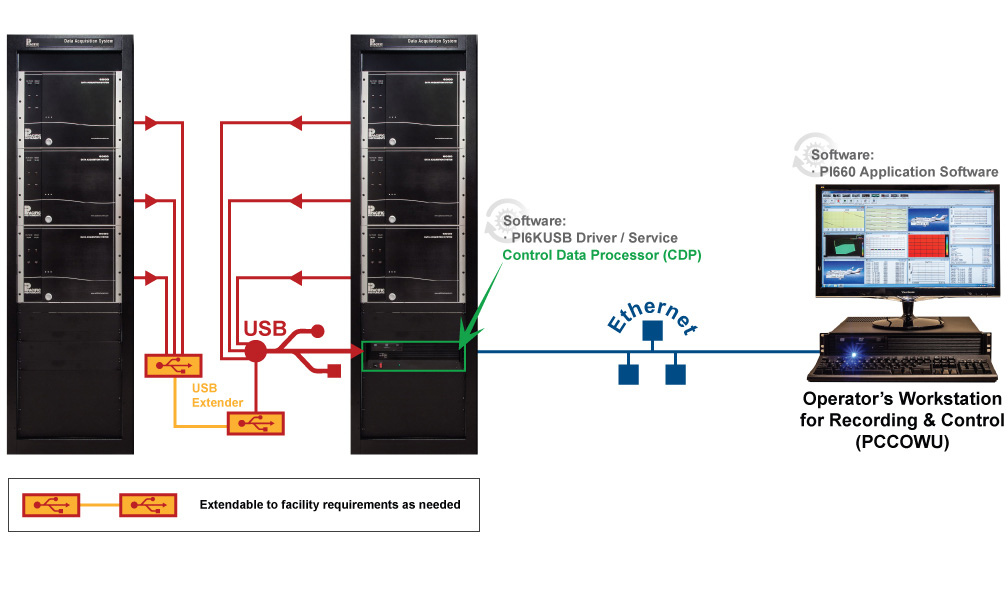

An Operator’s Workstation is the primary control and data recording point for the Series 6700 System. Typically installed in the control room, the Operator’s Workstation runs PI660 Data Acquisition Software for system setup, calibration, display, recording, distribution and export. Multiple, distributed systems are supported and controlled through a single Operator’s Workstation. A system can even be configured and used over wireless technology, allowing even greater control over the system. For example, a technician can change gain and filter settings on a touch screen tablet style PC while performing system checkouts and test readiness.

Data redundancy is optionally available and mounts on the controller board in each Series 6700 enclosure, creating a redundant recording point for the system. In the unlikely event the Operator’s Workstation or application software fails, data will continue to record in each enclosure and can be recovered from the system post-test.