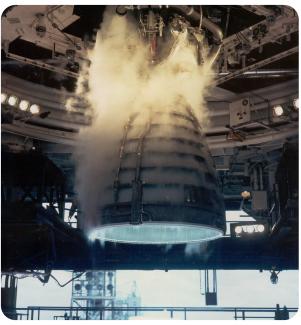

Precision Data Acquisition for Solid and Liquid Fuel Rocket Motor Testing

Engineered for Extreme Environments and Mission-Critical Accuracy

Pacific Instruments delivers high-performance data acquisition and signal conditioning solutions purpose-built for the rigorous demands of rocket motor testing. Whether you're validating solid fuel propulsion systems or analyzing liquid fuel engine performance, our systems provide the reliability, scalability, and speed required to capture critical data under extreme conditions.

We understand the challenges faced by test engineers and facility managers:

We understand the challenges faced by test engineers and facility managers:

- Legacy systems that lack scalability or integration

- High-speed and low-speed measurements requiring separate platforms

- Complex alarm monitoring across thousands of channels

- Tight timelines and budget constraints demanding rapid deployment

Our off-the-shelf (COTS) solutions are designed to solve these pain points—without compromise.

Core Features That Drive Rocket Motor Testing Success

- Series 6000 COTS Data Acquisition Systems

Proven, modular systems supporting tens to thousands of channels with flexible input, output, and DSP modules. - PI660 DataNet Software

Distributed control and recording software enabling a single operator to manage multiple remote systems with synchronized data streams. - High-Speed & Low-Speed Measurement Support

Unified platform for capturing both transient and steady-state data, reducing cost and complexity. - Advanced Alarm Monitoring

DSP-based logic and discrete output modules for real-time alerts on critical parameters across multiple channels. - High-Level Analog Outputs

Seamless integration with external control and recording systems via analog signal feeds. - Rapid Deployment & Scalability

Off-the-shelf hardware and software that can be installed and operational in days—not months.

Real-World Applications in Rocket Motor Testing

Pacific Instruments’ solutions are trusted by leading propulsion test facilities across the defense and aerospace sectors.

Case Study:

In 2011, a major customer selected our Series 6000 system after a comprehensive evaluation involving multiple suppliers. Time and funding constraints required a COTS solution that could be deployed quickly. Pacific delivered nine systems with over 2,500 channels, supporting both high-speed and low-speed measurements across multiple facilities.

Key outcomes:

- Reduced initial and operating costs by consolidating measurement platforms

- Enabled synchronized data recording across remote sites using PI660 DataNet

- Supported complex alarm logic and analog signal routing to legacy systems

- Provided a development system for process innovation using all available module types

Ready to Upgrade Your Rocket Motor Testing?

Let’s discuss how Pacific Instruments can help you achieve greater accuracy, efficiency, and control in your propulsion testing programs.