High-Channel Count Data Acquisition for Structural, Airframe, and Fatigue Testing

When it comes to structural testing of aircraft, precision, scalability, and reliability are non-negotiable. Pacific Instruments delivers high channel count data acquisition solutions engineered to meet the rigorous demands of airframe and fatigue testing. Our systems are trusted by aerospace leaders to validate structural integrity, support certification, and accelerate development timelines.

Test engineers face critical challenges:

Test engineers face critical challenges:

- Managing thousands of strain gage and bridge transducer channels

- Capturing high-speed failure data without overwhelming storage

- Operating in harsh environments with remote access requirements

- Integrating analog outputs with control systems

Pacific Instruments solves these challenges with robust, flexible systems that scale to meet the complexity of modern aircraft testing programs.

Core Features That Power Structural Testing Success

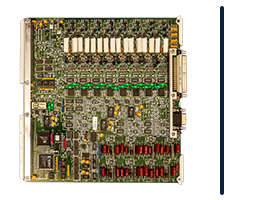

- High Channel Count Scalability – Supports thousands of channels for strain gage, bridge, and other transducer inputs.

- History Buffer for Failure Capture – Automatically stores high-speed data before and after structural failures—without logging unnecessary samples.

- Real-Time Display & Monitoring – Ethernet-connected workstations provide live data visualization for immediate test validation.

- Remote Interface Capability – Fiber optic interfaces extend control and data access up to 6,000 feet—ideal for hot, dirty test environments.

- Analog Outputs for Load Control Integration – Seamlessly connects to structural load systems for synchronized control and measurement.

- Modular System Architecture – Configure systems from tens to thousands of channels across multiple independent test setups.

Real-World Success in Aircraft Structural Testing

Airframe Certification

Aircraft manufacturer selected Pacific Instruments’ Series 6000 systems for both structural and fatigue testing of the Premier I airframe in Wichita, Kansas. The program involved over 2,400 channels, primarily strain gages and bridge transducers, organized across five independent systems.

Key outcomes:

- Enabled simultaneous testing of multiple components and airframes

- Delivered real-time data to engineers via Ethernet-connected display workstations

- Used history buffer to capture high-speed data during structural failures

- Supported long-duration fatigue tests with low-rate sampling and triggered high-rate recording

- Integrated analog outputs with control systems applying structural loads

- Operated reliably in harsh test environments with remote fiber optic interfaces

Pacific Instruments was selected over multiple competitors based on performance and cost.

Ready to Strengthen Your Structural Testing Program?

Let’s talk about how Pacific Instruments can help you achieve greater accuracy, efficiency, and control in your aircraft testing initiatives.