Precision Turbine Test Solutions for Aircraft Engines and Power Turbines

High Channel Count Data Acquisition Systems | Signal Conditioning Solutions | Dynamic & Static Testing

Empowering Turbine Testing with Scalable, High-Performance Data Acquisition

Pacific Instruments delivers advanced data acquisition and signal conditioning systems engineered for the high-stakes world of turbine testing. Whether you're validating aircraft engines or optimizing power turbines, our solutions provide the precision, scalability, and reliability needed to meet industry demands and accelerate innovation.

Pacific Instruments delivers advanced data acquisition and signal conditioning systems engineered for the high-stakes world of turbine testing. Whether you're validating aircraft engines or optimizing power turbines, our solutions provide the precision, scalability, and reliability needed to meet industry demands and accelerate innovation.

We help engineering teams overcome key challenges—managing high channel counts, capturing dynamic and static data, operating in extreme environments, and detecting early signs of mechanical failure. Our systems are designed to simplify complex test setups and deliver actionable insights that improve safety, performance, and efficiency.

Core Features That Meet Industry Demands

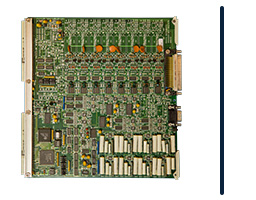

- High Channel Count Capability: Supports thousands of input channels for full-system and component-level turbine testing.

- Modular Signal Conditioning: Configurable for strain, pressure, temperature, vibration, and other sensor types—ideal for dynamic and static testing scenarios.

- Blade Failure Detection & Monitoring: Real-time analysis of vibration and stress signals to identify early signs of blade fatigue, cracking, or imbalance—minimizing risk and preventing costly failures.

- Real-Time Data Acquisition & Analysis: Enables immediate feedback during test runs, reducing downtime and improving test efficiency.

- Ruggedized Hardware for Harsh Environments: Built to withstand high temperatures, vibration, and electromagnetic interference typical in turbine test cells.

- Seamless Integration with Existing Infrastructure: Compatible with industry-standard protocols and software platforms for streamlined deployment.

Industry-Specific Applications

Aircraft Engine Testing

Pacific Instruments' systems are trusted by leading aerospace manufacturers to validate engine performance, thermal behavior, and structural integrity. Our blade failure detection capabilities help identify fatigue and stress issues before they escalate, ensuring safer and more reliable engines.

Power Turbine Testing

Energy providers rely on our systems to monitor turbine efficiency, detect early signs of wear or blade degradation, and ensure compliance with regulatory standards. Our scalable architecture supports both prototype development and long-term operational testing.